Our areas of expertise and experience are in thermoplastic and thermoset fiber reinforced products, value-added laminations and coasting, natural and synthetic fibers and kraft and tissue papers – all tailored to our customers’ process and performance requirements.

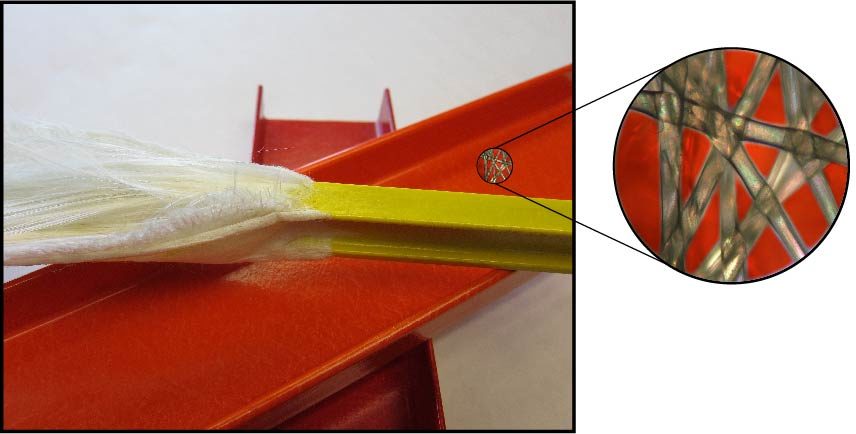

Xamax provides critical surfacing veils material that is applied to FRP Thermoset products. These materials are engineered to give end-use products, like the FRP Railing (pictured), a smooth feel and aesthetic look; while also providing protection such as UV and corrosion resistance. You can’t always see our material, but without it, you’ll notice a much more unpleasing end-use product. Our surfacing veils for FRP Thermosets enhance your final product.