Polyethylene Terephthalate Film (PET Film)

Polyethylene Terephthalate Film (PET Film) is the most common thermoplastic polymer resin of the polyester family. It is used in fibers for clothing, containers for liquids and foods, thermoforming for manufacturing and in combination with glass fiber for engineering resins.

Olefin Films

Olefin Films – Olefins, also called polyalkenes, are the largest class of commodity thermoplastics. They are polymers of simple alkenes such as ethylene, propylene, butenes, pentenes and copolymers thereof. The two most important polyolefins are polyethylene (PE) and polypropylene (PP).

Olefin films include: Polypropylene Interleave Film (PP Film), Polyethylene Film (PE Film), Low Density Polyethylene Film (LDPE Film), Linear Low Density Polyethylene Film (LLDPE Film)

Xamax Specialty Films

Specialty Films – Xamax offers specialty films to solve difficult applications. Our specialty films include: Polyamide Film (PA Film), Poly Lactic Acid Film (PLA Film), Polyphenylsulfone Film (PPSU Film), Polyphenylene Sulfide Film (PPS Film), Polyvinyl Chloride Film (PVC Film), Polyimide Kapton (PI Film)

Polyester Films

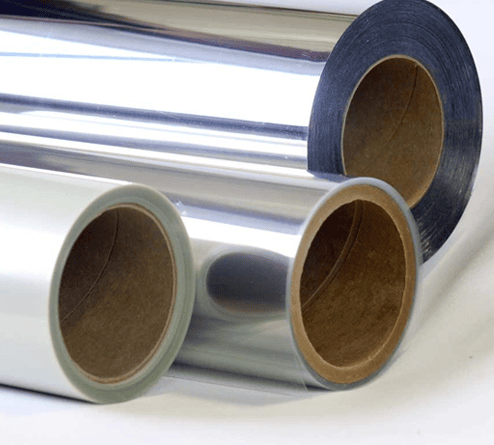

BOPET Film

BOPET (Biaxially Oriented Polyethylene Terephthalate) is a polyester film made from orientated polyethylene terephthalate (PET). BOPET is used because of its high tensile strength, chemical and dimensional stability, transparency, reflectivity, gas and aroma barrier properties and electrical insulation. BOPET is known as the trade names Melinex® and Mylar®.

Polyethylene Terephthalate (PET) Film

PET is an excellent water and moisture barrier material,making it widely used in plastic bottles for soft drinks. For certain specialty bottles, such as those designated for beer containment, PET sandwiches an additional polyvinyl alcohol (PVOH) layer to further reduce its oxygen permeability.

Biaxially oriented PET film (often known by one of its trade names, “Mylar”) can be aluminized by evaporating a thin film of metal onto it to reduce its permeability, and to make it reflective and opaque (MPET). These properties are useful in many applications, including flexible food packaging and thermal insulation. See: “space blankets”. Due to its high mechanical strength, polyester film/PET film is often used in tape applications, such as the carrier for magnetic tape or backing for pressure-sensitive adhesive tapes.

Non-oriented PET sheet can be thermoformed to make packaging trays and blister packs. If crystallizable PET is used, the trays can be used for frozen dinners, since they withstand both freezing and oven baking temperatures. Opposed to amorphous PET, which is transparent, crystallizable PET or CPET tends to be black in colour.

When filled with glass particles or fibers, PET becomes significantly stiffer and more durable.

Our polyester films can be used for a variety of end uses. PET is also used as a substrate in thin film solar cells

Glass/Polyester Magnet Wire Insulation

Xamax products create a layer of Glass/Polyester insulation on Magnet Wire which provides a protective covering and insulation barrier