At the intersection of innovation and engineering, we find thermoplastic materials reshaping various industries with their remarkable versatility. Characterized by their reusable nature, thermoplastic resin, and polymers earn their place as sustainable alternatives in numerous applications.

At Xamax Industries, Inc., our passionate team of experts is dedicated to revolutionizing industries with advanced thermoplastic materials. We offer high-quality thermoplastic sheets, composites, and more. From aerospace to automotive, the applications are vast and diverse.

An Overview of Thermoplastic FRP

Thermoplastics become softer and melt when heated and then harden again when cooled. This process of reaching the softening and melting temperature can be repeated as often as you want without affecting the material’s properties in either state so that it can be re-molded and re-shaped.

This is where thermoplastic fiber-reinforced plastics (FRP) come in handy. By incorporating reinforcing fibers into the mix of thermoplastic materials, we create a strong and durable product that can withstand strenuous conditions.

FRP composites make use of a thermoset plastic material. This material is combined with a strong reinforcing fiber, such as glass or carbon, to create a product that can withstand high temperatures and pressures.

Including fibers in FRP has multiple benefits. It reduces weight and improves elastic modulus and mechanical strength. This means that thermoplastic composites are more reliable when it comes to performance and durability. Additionally, they provide a lightweight and strong solution for your needs.

Examples of Thermoplastic FRP Applications in Various Industries

Thermoplastic FRP finds utility in many sectors due to its exceptional durability, flexibility, and strength. Here are some examples of how these composites are transforming various industries:

- Automotive: FRPs have significant worth as alternatives to metal in the frames of high-end cars and in the sidings of trucks and trailers. Thermoplastic composites are ideal for automotive parts as they have high strength and stiffness and can provide fuel efficiency.

- Aerospace: FRPs offer reduced weight while maintaining equal or greater strength in comparison to aluminum sheets. They can be used in the production of composite aircraft structures, such as wings, fuselages, and tail components.

- Construction: FRPs can be utilized to upgrade the load-bearing capacity or repair damages in existing structures, such as slabs, columns, or beams. Thermoplastic polymers also offer increased longevity and reduced maintenance since the material does not corrode.

- Marine: FRPs can be used for boat hulls, decks, gunwales, and masts. Since thermoplastic FRP is waterproof and extremely durable, it does not require any additional protection or coating against the elements.

What We Offer:

- Surfacing laminates for polypropylene, nylon, and other resin systems

- Refrigerated transport surface laminate

- Trailer liners with excellent scuff resistance

- Adhesive films to bond between olefin and other chemistries

- PET veils for providing smoother finish to thermoplastic lamination

Benefits and Features:

- Creates a smooth and finished surface over thermoplastic fiberglass layup

- Provides better resistance to UV light

- Helps to hide fiber print through

- Adds scuff resistance

- Leaves surface easily cleanable, smooth, and generally bacteria resistant

Applications

Refrigerated Trailers

Integral refrigerated wall laminate for smooth, cleanable surface that generally resist bacteria. Aerodynamic trailer skirt laminate with excellent scuff protection.

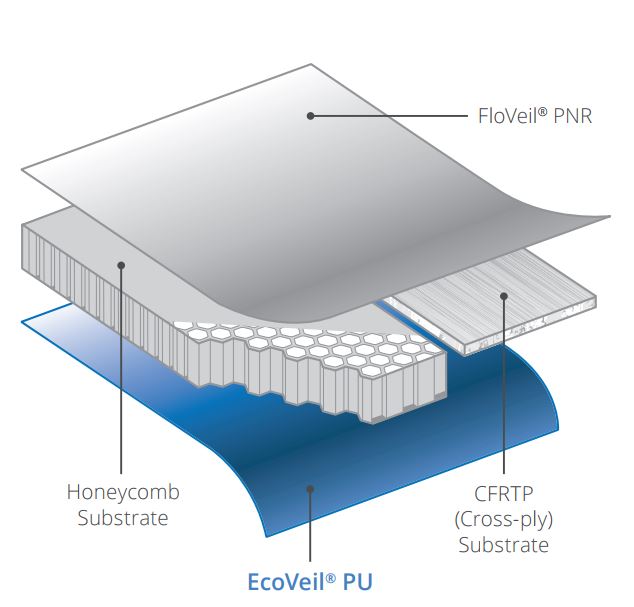

EcoVeil PU

Honeycomb Sandwich Panel Surface Laminate A smooth layer to provide a finished surface or be painted.

Turn to Xamax Industries for Your Thermoplastic FRP Needs

Thermoplastic sheets and composites are revolutionizing industries with their versatility and sustainability. Xamax Industries, Inc. is committed to delivering high-quality thermoplastic materials that surpass expectations. From automotive to aerospace, these materials offer strength, durability, and weight reduction, making them ideal for a range of applications.

Ready to harness the power of thermoplastic FRP for your industry? Contact us today to explore our top-notch thermoplastic solutions. Let’s work together to elevate your projects and create something truly extraordinary. You can also browse our selection of products and services to learn more about the possibilities.