Xamax provides a layer of high-performance laminates or films that are used to provide an attractive and protective outer cover in a variety of applications. Tractor trailers were an early adapter where they are used in side skirts and liner panels. New uses include RVs and construction materials.

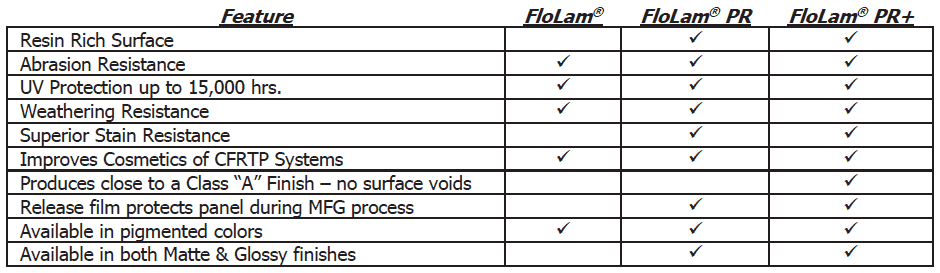

FloLam® Surface Laminate Series

FloLam® surfacing industrial laminates were designed to provide a smooth, resin rich surface over the top of various thermoplastic laminates and substrates where aesthetics and surface quality are demanded. It is specially engineered to withstand the rigorous processing temperatures of any continuous fiber reinforced thermoplastic materials (CFRTP) systems and thermoplastic sandwich panels. The FloLam® surfacing film and laminate provides a substantial level of protection and surface cleanliness to a broad range of surfaces, even under long term exposure to UV light, moisture and bacteria. With exceptional UV protection, weatherability and abrasion resistance, our FloLam® surface custom laminates are well suited for many outdoor applications, and typically provides fade resistance and color stability over long-term exposure.

The FloLam® PR surfacing laminate integrates a special release film and includes all the benefits of the FloLam® surface laminate. Additionally, the use of the release film allows a clean and easy removal from the composites without transfer of any residues. The surfacing film also acts as a protective cover to the composite laminates that can be removed by the end user later on.

The FloLam® PR+ is the ultimate enhancement for thermoplastic composites for both surface protection and aesthetics. It is specially engineered to produce a close to Class “A” finish – no surface voids.

The FloLam® series technology is patented.

FloVeil® Surfacing Films

FloVeil® PNR is a PET(Polyethylene terephthalate) film with an adhesion layer. This FloVeil® PNR film layer will provide a high level of surface enhancement, similar to FloLam® PR and PR+, except the polyester cover sheet is permanent and remains with the substrate. In addition, the FloVeil® PNR outer surface is treated to help bond various pressure sensitive adhesives (PSA) and urethane adhesives/hot melts.

FloVeil® PP-FR acts just as regular FloVeil® surfacing film does, but we add flame retardancy to the overall finished composite. FloVeil® PP-FR is tested in accordance with ASTM 84-14 to meet a flame spread index under 200. FloVeil® PNR provides excellent UV resistance

FloCore®

FloCore® is a high bulk, copolymer film designed for PP(polypropylene) based thermoplastic composites. FloCore® surfacing film should be used where you have severe irregularities and imperfections in your substrate; and in conjunction with either FloLam® series product or a FLoVeil® PNR.

With FloCore®, you can quickly and cost effectively add value and bulk to thermoplastic composites. For example, FloCore® can be added to a substrate to alleviate severe imperfections; followed by FloLam® material added as the final layer.

EcoVeil® PBS Bonding Scrim

Our EcoVeil® product is a 100% polyester fabric material, specially treated to bond adjacent materials to each other with strength and stability. This surfacing non-woven has a micro dot pattern that provides a smooth and uniform fiber density. EcoVeil® also has even fiber distribution, which allows for excellent bonding to various thermoplastic laminates and substrates. Its special attributes, such as “high Z directional tensile strength,” excellent uniformity and thickness, provide the best performance to the end user.

Our EcoVeil® PBS product is available in a USDA/FDA grade. It is also a specified product in many US and international patents related to thermoplastic products.

EcoVeil® is another registered trademark of Xamax Industries, Inc.

EcoVeil® PU Bonding Film

EcoVeil® PU Bonding Film is designed to be used directly on top of polypropylene based polymers and copolymers including homopolymer PP resin rich substrates. Formulated with the proprietary bonding chemistry used in FloVeil® PNR, the bonding film attaches to the PP surface of the substrate when the proper amount of temperature, pressure and dwell time are induced during the lamination process between the two. The resulting bond between the film and the substrate becomes a permanent destructible bond..

EcoVeil® PU Bonding film’s outer surface contains a polyurethane-friendly treatment which enhances the bonding of engineered adhesives—especially PU adhesives—to the surface. With this enhanced bonding surface, the finished composite can now be affixed and held in place securely, whereas it would have been impossible to bond to the original exposed PP surface. EcoVeil® PU Bonding Film is intended for interior applications unless the outer surface is painted or over wrapped with a UV resistance decal.